Findings Friday Part 4: Find Out How Stuller Makes It

Follow along as we demonstrate our casting process, build a custom ring from findings, and set the stones in a ring.

Findings are crucial for a jeweler as they serve as the building blocks that bring a piece of jewelry together and ensure its durability, functionality, and aesthetic appeal. These small metal components connect different elements of jewelry and come in various materials, finishes, and styles — providing versatility and limitless possibilities for customization to match any customer’s style.

This year we began to showcase how we manufacture our findings through a series of highlighted stories each month on Instagram called #FindingsFriday. In this quarterly update, follow along as we demonstrate our casting process, build a custom ring from findings, and set the stones in a ring.

Findings not only provide structural support but also enhance the overall design, allowing the jeweler to create unique and imaginative pieces. To catch a glimpse of the creativity brewing within our facility, let’s explore some of our recent #FindingsFriday highlighted stories.

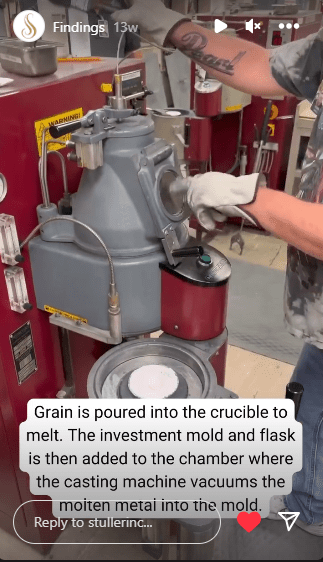

The Casting Process

Step 1: Grain is poured into the crucible to melt. The investment mold and flask are then added to the chamber where the casting machine vacuums the molten metal into the mold.

Step 2: The flask is then brought to a staging area while the metals cool and wait to be removed from investment and sandblasted.

Step 3: Trees are cleaned in a three-step cleaning tank.

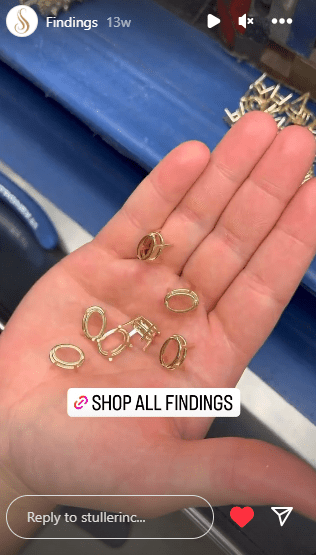

Step 4: After being tumbled, settings are clipped from the tree and ready for stock.

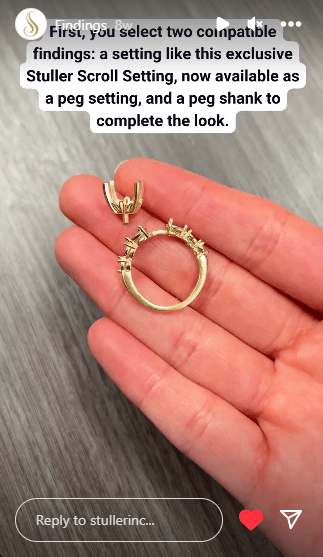

Building a Custom Ring from Findings

Step 1: First, select two compatible findings: a setting like this exclusive Stuller oval 4-prong scroll setting, now available as a peg setting, and a pear graduated peg shank to complete the look.

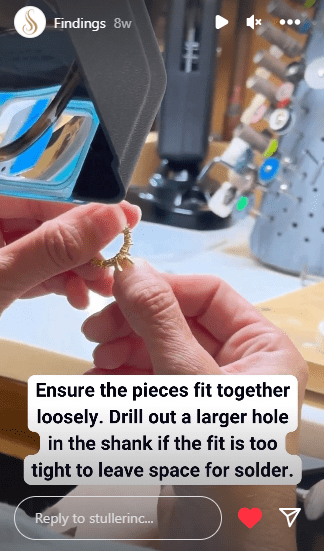

Step 2: Ensure the pieces fit together loosely. Drill out a larger hole in the shank if the fit is too tight to leave space for solder.

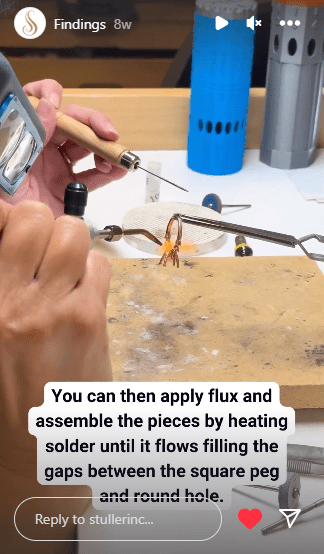

Step 3: You can then apply flux and assemble the pieces by heating solder until it flows — filling the gaps between the square peg and round hole.

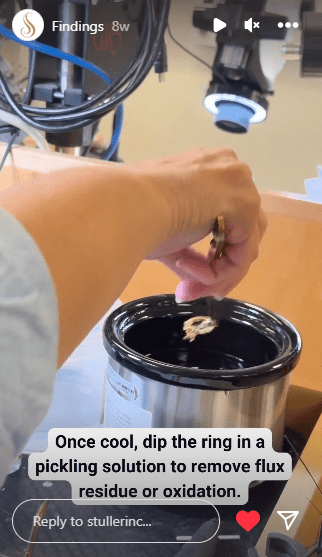

Step 4: Once cool, dip the ring in a pickling solution to remove flux residue or oxidation.

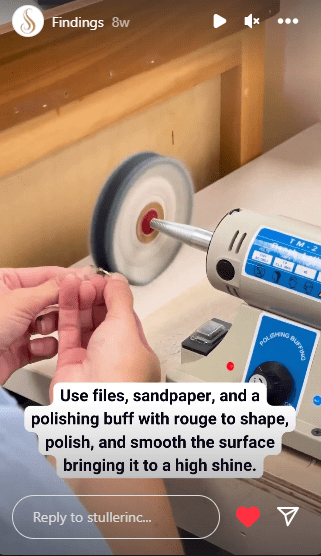

Step 5: Use files, sandpaper, and a polishing buff with rouge to shape, polish, and smooth the surface, bringing it to a high shine.

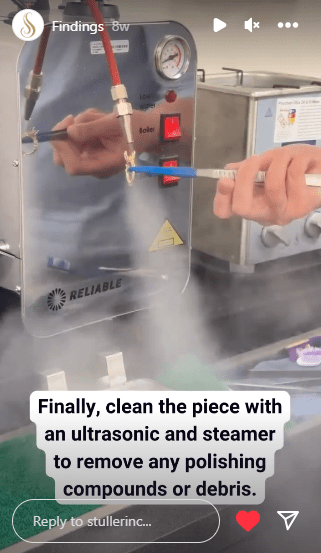

Step 6: Finally, clean the piece with an ultrasonic steamer to remove any polishing compounds or debris.

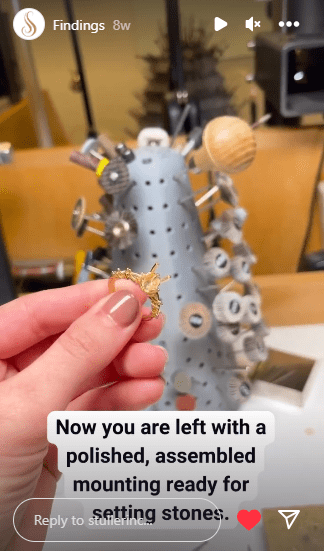

Step 7: Now you are left with a polished, assembled mounting ready for setting stones.

The Stone Setting Process

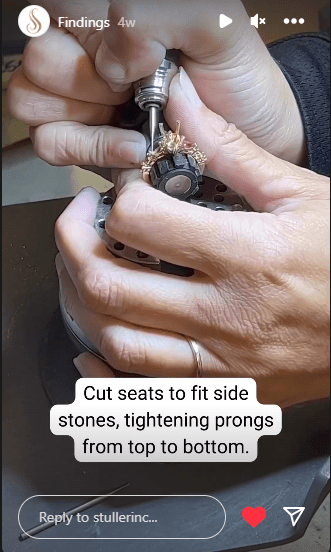

Step 1: Cut the seats to fit side stones, tightening prongs from top to bottom.

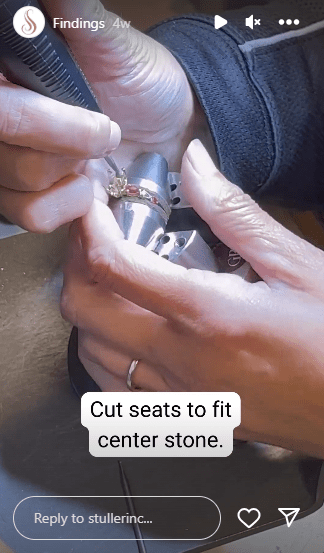

Step 2: Cut the seats to fit center stones.

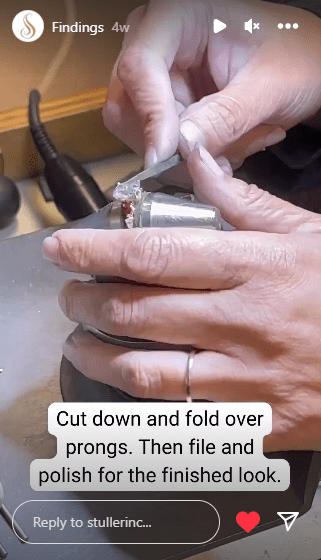

Step 3: Cut down and fold over prongs. Then file and polish for the finished look.

Step 4: Enjoy a perfectly set ring ready to shine!

Ultimately, the quality and selection of findings significantly contribute to the quality and success of a jeweler’s work, ensuring that their creations are visually stunning, long-lasting, and function as intended.

For all the jewelry findings you need in one place, look no further than Stuller, and be sure to check out our newest catalog, Findings & Metals 2024–2025.

To learn more about what we’ve showcased for #FindingsFriday in 2023, check out these previous blogs: