Findings Friday: Find Out How Stuller Makes It

Take a behind-the-scenes look at how we manufacture the findings used to create multi-gemstone graduated drop earrings.

As a wholesale jewelry manufacturer, our teams create an astronomical amount of product in-house. For all of the jewelry findings you need to create custom jewelry, look no further than Stuller.

We’re excited about our new series of highlighted stories called #FindingsFriday on Instagram. Today, we’re giving you an inside look at how we make the findings and componentry needed for designing multi-gemstone graduated drop earrings.

We’ll take you through our processes step-by-step from the beginning to the finished product, and show you the featured findings we used. Let’s dive in!

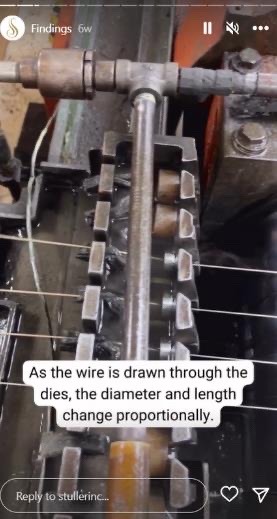

The Wire Drawing Process

This process is necessary to reduce the wire’s thickness in order to make the wire gauge needed for earring posts, jump rings, ear wires, and more.

Step 1: Precious metal rods are drawn through diamond draw dies, which ensure consistency and finish gauge control.

Step 2: As the wire is drawn through the dies, the diameter and length change proportionately.

Step 3: The finished gauge wire is then ready to be held in inventory until it is time for secondary operations.

The Jump Ring Process

Step 4: Wire is tightly coiled around an arbor that is the same size of the inner dimensions of the jump ring.

Step 5: The arbor is then passed through this machine’s internal saw mechanism, which slices the coiled wire into jump rings.

Step 6: Hundreds of finished jump rings (JR13) are the end result, and they are each checked for perfection.

The Bishop Hooks Process

Step 7: To begin the process, wire is inserted into the machine to be karat-stamped with the metal quality of the specific run taking place.

Step 8: The karat-stamped wire is then fed through the tool to be shaped into the corresponding bishop hook series being made.

Step 9: Hundreds of bishop hooks (21611) are the result, and each one is thoroughly inspected to ensure it meets Stuller’s high-quality standards.

How It's Made: 14K Multi-Gemstone Graduated Drop Earrings

Step 10: The individual components (dangles and links) are pieced together to prep for stone setting.

Step 11: With a very precise hand, an Orotig Evo White Laser Welder (14-0192:200000:T) is used to solder the jump rings closed.

Step 12: Then we set all the gemstones: Aquamarine, Blue Zircon, Moissanite, Topaz, and Sapphire.

Finally: The Finished Piece

While this custom crafted piece is not a part of the Stuller fine jewelry line, the findings and components necessary to make them are all items we offer to our customers. Shop the jump ring, bishop hook, round bezel dangle, pear natural diamond bezel-set link, and round natural diamond bezel-set link on Stuller.com today.

Be sure to check out Stuller’s newest #FindingsFriday story on Instagram today to follow all the videos from the beginning processes to this beautiful, finished pair of multi-gemstone graduated drop earrings. Be sure to join us each month for a new series of #FindingsFriday.

Laura Ann Settoon

Former Product Manager, Findings

Laura Ann joined the Stuller team as the Findings Merchandising Intern in the Summer of 2022. As a recent graduate in Strategic Communication with minors in both Psychology and in Marketing from Southeastern Louisiana University, she uses her knowledge to guide her in learning the ways of the industry. Since becoming a permanent team member, Laura Ann has expanded her position to both Findings and Fabricated Metals, ultimately driving her ability to provide and educate jewelers with the right products for every job.