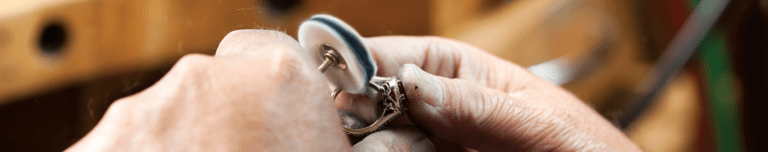

Kickstart Your Jewelry Repair Business With 5 Easy Tips

Jewelry repair is an underlying revenue stream that pays the bills when things get slow. Did you know repair averages anywhere from 10% to 15%

Jewelry repair is an underlying revenue stream that pays the bills when things get slow. Did you know repair averages anywhere from 10% to 15%

Mark your calendars! Stuller’s Bench Jeweler Workshop begins Friday, March 23 where our 3rd Annual Battle of the Benches competition will kick off. This year,

Few can argue that jewelry repair is an underlying revenue stream that pays the bills when things get slow. In fact, repair averages anywhere from

Over the past year, our Tools Department has spent countless hours developing the 2016-2017 Tools Catalog. They researched years of your comments from past catalogs

Stuller’s new Tools catalog will be landing on your doorstep any minute. Our experts in the Tools department have spent countless hours curating the best