Eleven Things to Know About Our Newest Findings Catalog

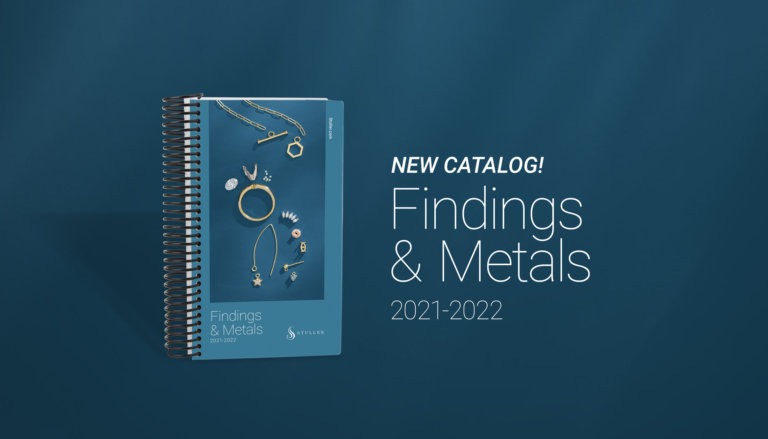

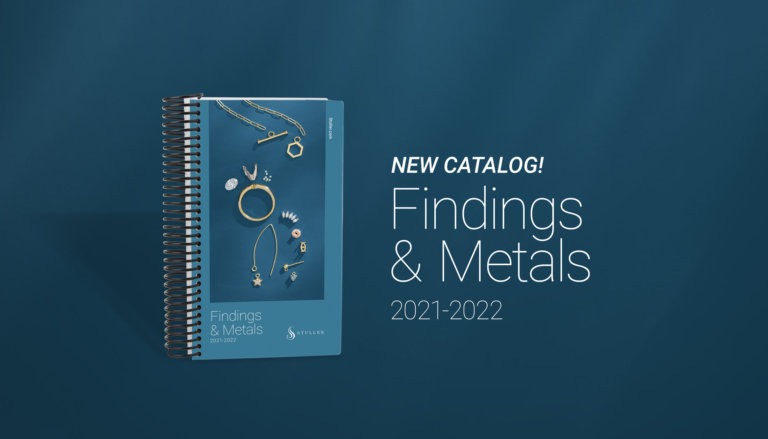

Stuller is very excited to release Findings & Metals 2021-2022 — a comprehensive guide to Stuller’s findings, classic mountings, fabricated metals, and loose stones assortment. For

Stuller is very excited to release Findings & Metals 2021-2022 — a comprehensive guide to Stuller’s findings, classic mountings, fabricated metals, and loose stones assortment. For

Stuller recently launched a partnership with Jordan Mantzke, also known as Modern Goldsmith, to promote tools and other things a new jeweler would need to

Are we really just 37 days from Christmas? There’s no doubt about it. And as each passing day unwinds ever faster, Stuller will get you what you need just in time. So far in our Facebook

Think of when you went above and beyond for someone— or when someone went above and beyond for you. It’s always special to leave an

As Stuller celebrates 50 years in the industry, another huge milestone is being celebrated: Earth Day, created 50 years ago today. Since that day in

As Stuller celebrates 50 years in the industry, it’s a perfect time to look back on our history and the numerous milestones we’ve achieved. Among

Do you know how much palladium costs per ounce? If you answered “no,” you’re like most of us. It’s not a big a part of

What’s not to love about platinum? It’s the densest of the precious metals, can stand up to a lifetime of everyday wear, and is even

Over the last few months, I’ve talked a lot about how to customize your packaging to enhance your brand. What you say (and how you say

Lost wax casting blends old and new in truly remarkable fashion. Our industry is constantly changing, adapting ancient techniques to modern technology. So, we’ve asked