How to Build a Booming Jewelry Repair Business

On average, your jewelry repair business contributes 15% or more to your top line, while accounting for 60% of your foot traffic. Most jewelers aren’t

On average, your jewelry repair business contributes 15% or more to your top line, while accounting for 60% of your foot traffic. Most jewelers aren’t

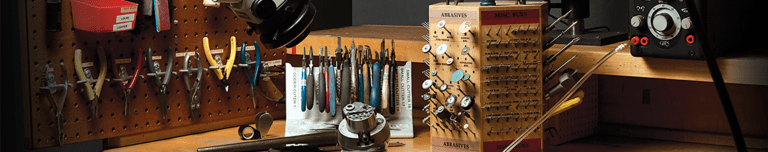

An organized shop is a more efficient one. How much time do you waste daily looking for tools? If you don’t think you do, log

Though not quite as extraordinary as say, interstellar cosmic dust or remnants from a shooting star, dust in your store can reap unexpected rewards. In day-to-day activities

Rouges are a must on any jeweler’s bench. They buff and polish, smooth and shine. There are many colors with even more uses, but no

Folks have been calling me “the Tool Guy” for as long as I can remember. Before I found my true calling, I worked as a

Many folks call me throughout the week who are either new to the business, or have been in business, but don’t know where or how to